Precision Hardware

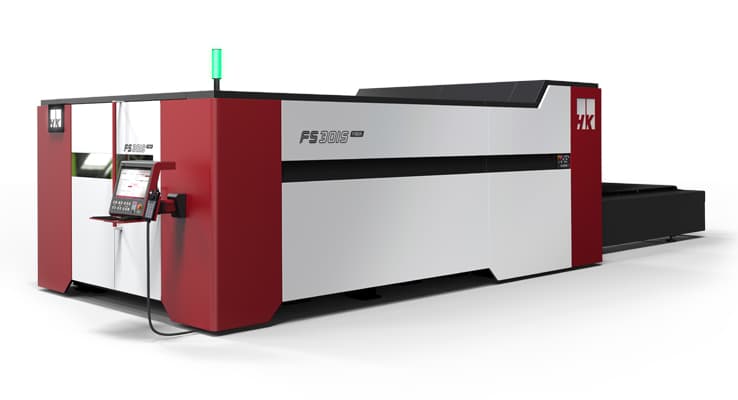

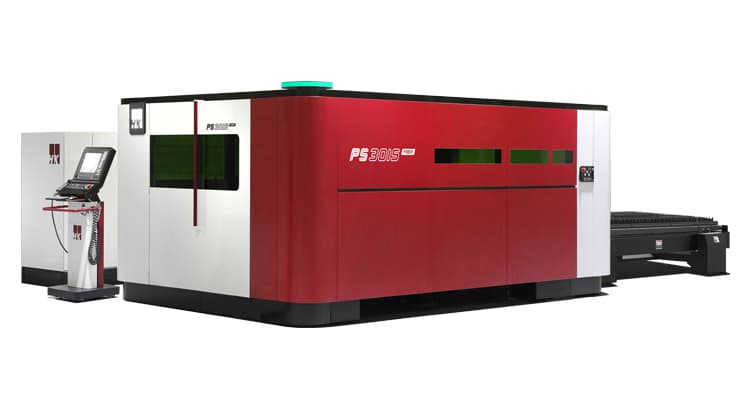

Use one of our Fiber laser systems and you can forget about back reflections that could damage your laser cutter. These fiber laser machines are more cost-effective and require less maintenance.

GSS Machinery is a combination of engineering and technical expertise. They create custom machinery prototypes and pilot plants, as well as full production lines.